Using the power of GenAI to unlock the next level of optimization for industries

Leveraging GenAI, we optimize industries with real-time insights, intelligent automation, and

predictive analytics for smarter, more efficient operations.

AI applications in industry

GenAI is transforming industrial operations with intelligent automation and

predictive insights across various domains:

Production Scheduling

Unleash the potential of production scheduling with Genindustry, our AI-based SaaS optimizer. It redefines production planning, ensuring accurate scheduling, and optimal resource allocation while effortlessly managing complex constraints.

- Faster & Smarter Production Planning – Reduce planning time from days to minutes with AI-driven scheduling.

- Minimized Downtime & Improved Efficiency – Achieve 15% reduction in changeover downtime for seamless operations.

- Optimized Inventory Management – Prevent shortages by cutting stockout items from 4% to 2% with AI-powered forecasting.

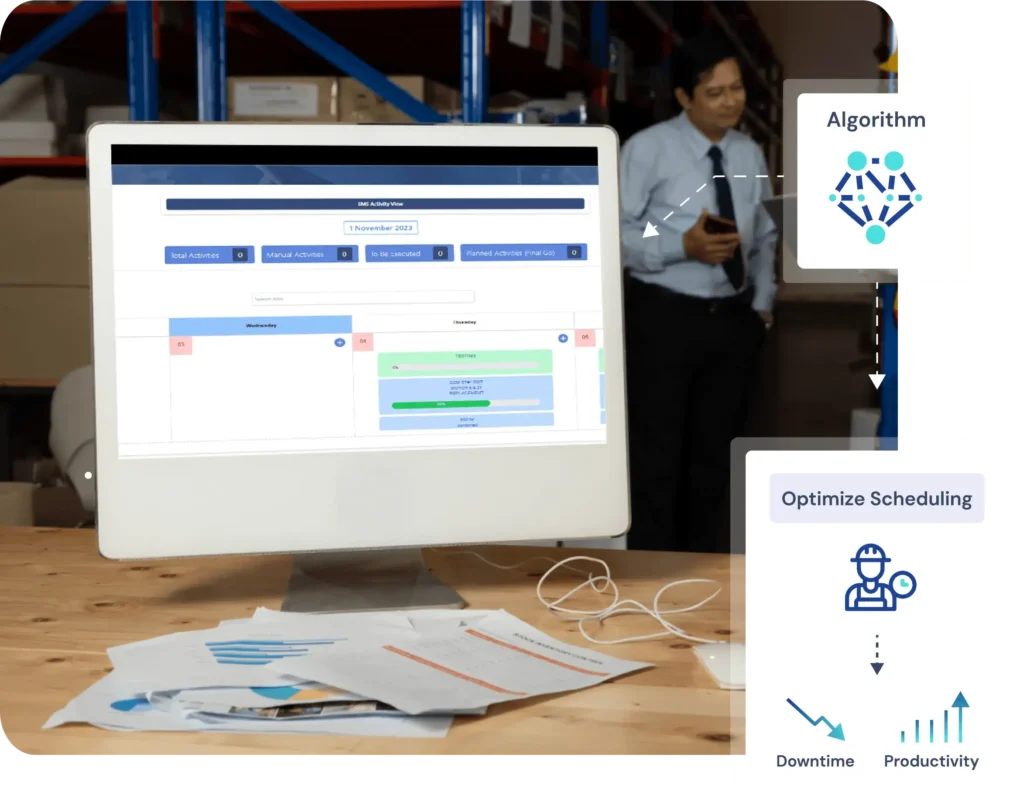

Manpower optimization

Experience the future of factory operations with our patented AI-based optimizer. Achieve flawless line balancing, precise scheduling, and efficient manpower allocation, revolutionizing your production planning effortlessly.

Eliminates Manual Scheduling – AI automates complex scheduling, saving time and effort.

Real-Time Workforce Visibility – AI-powered dashboards provide instant insights into workforce metrics.

Boosts Productivity & Engagement – Automating scheduling reduces administrative burdens and enhances employee motivation.

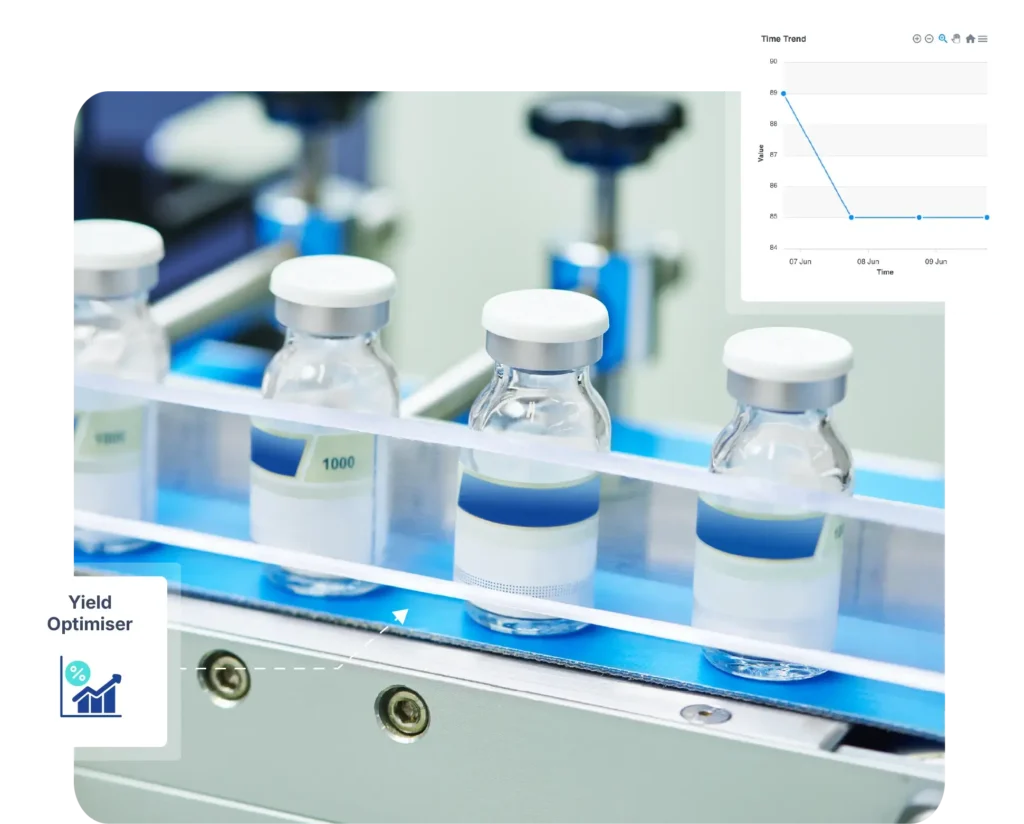

Yield optimization

AI-powered yield optimization minimizes process variability, ensuring consistent output and maximum efficiency. By optimizing resource utilization, it increases production yield while reducing waste. Real-time insights enable manufacturers to fine-tune operations for continuous improvement.

Consistent Yield – AI identifies and mitigates variability factors to ensure stable production outcomes.

Better Process Management – Analyzes all process steps to simplify operations and improve efficiency.

Optimized Performance – AI-driven insights help fine-tune processes for maximum productivity and minimal waste.

Digital twins

Creating real-time virtual models as digital twins enables industries to simulate operations and optimize performance. These AI-driven models analyze workflows, identify inefficiencies, and enhance decision-making.

We have developed digital twins for critical industrial processes, enabling real-time monitoring, predictive insights, and optimization.

Blast Furnace – Optimizes burden distribution, fuel efficiency, and process stability.

Power Plant Boiler – Enhances combustion control and prevents failures.

Al Potline – Ensures stable aluminum production with AI-driven monitoring.

Steel Melt-Shop – Improves metallurgical control and minimizes defects.

Why Choose Us?

Book A Demo Now

Empowering top enterprises through our excellance

Useful Links

Subscribe Now

Don’t miss our future updates! Get Subscribed Today!

©2019. GenIndustry. All Rights Reserved.